Firing Texture Molds

All of these molds are sold out but I will leave this here for the info on firing!

First note. Never cut the glass to the size of the edge of the mold….always keep it in a bit. If the glass melts over the edge cracking will occur.

Second note….if you are using a heat sensitive glass like Wissmach Lumi you will have to find the sweet spot for the top temp in your kiln. In these schedules I have been going to 1420 in my JenKen but i my large Denver I have to lower that to 1390 to keep the effect. After your first firing if you do not see the rainbows lower your top temp by 20 degrees and go from there. You can also put thinfire on the prepared mold which can help keep the effect. Non lumi glass I would go to 1420 if using COE 96.

I am firing these 2 different ways and there is a schedule for both.

* One way is putting the base glass capped with clear directly on the prepared mold. If using Wissmach luminescence you must put the lumi face down to the mold. When doing this in one firing you must use a good bubble squeeze schedule and I also use clear powder between the glass layers as insurance.

*The other is prefiring the 2 layers of glass and then in a 2nd firing placing it on the mold. On these if using Wissmach Luminescence I fire them lumi down onto thin fire with clear on top. When doing this in one firing you must use a good bubble squeeze schedule and I also use clear powder between the glass layers as insurance.

You will find the best way for you.

so……each mold will have 2 schedules for the firing. My schedules are for 96. Adjust for coe 90 by raising temps 25 degrees and annealing at 900.

On Coe 96 I am only prefiring to 1350. At that temp the glass is totally sealed and you do not have to worry about getting bubbles. It is also a great way to preserve as much color on Lumi as much as possible. 1350 is not the temp on the mold…..just if you are prefiring.

My Prefire Schedule

This schedule is for those that want to prefire 2 layers of glass BEFORE putting them on a texture mold. I also use this schedule for any of my work with 96 where I want to prefire the base glass of 2 layers.

Prefire….

*250/1100/20 (this hold is adjusted by the size of the piece. For the size of these texture molds this is enough of a hold in the bubble squeeze temp zone.)

*50/1225/20 (again this hold is determined by the size of the piece)

*450/1350 /5 (this is not a full fuse but it does seal the glass so that no air can be trapped in the next firing. No need to go higher but you can also full fuse if doing a load with other work.)

*9999/950/90

*100/700/0

I fire Lumi face down on thin fire for a Prefire…….directly on the mold I am using Zyp on the molds. You can also use thin fire on the molds. Find which you like best. With thinfire sometimes it can even be “too much” lumi so it is up to the look you want.

Sun/Moon Texture Mold - 11” $42

Glass 2 layers no prefire

250/1100/20

50/1225/20

450/1420/5

9999/950/90

100/700 off

on the Sun Moon if you are using colors as I did in this one I would prefuse the 2 layers first. I got a few annoying bubbles firing the 2 right on the mold on this yellow/orange one. I did have extra powder between the layers and that may have been the cause but it is also larger.

Glass 2 layers already Prefired

250/1420/5

9999/950/90

100/700 off

Victorian Texture Mold - 11” $42

Keep in mind on this mold you can also fire rectangles and squares. Makes really nice sets!!

Glass 2 layers no prefire (clear powder between layers)

250/1100/20

50/1225/20

450/1420/5

9999/950/90

100/700 off

Glass 2 layers Prefired

250/1420/5

9999/950/90

100/700 off

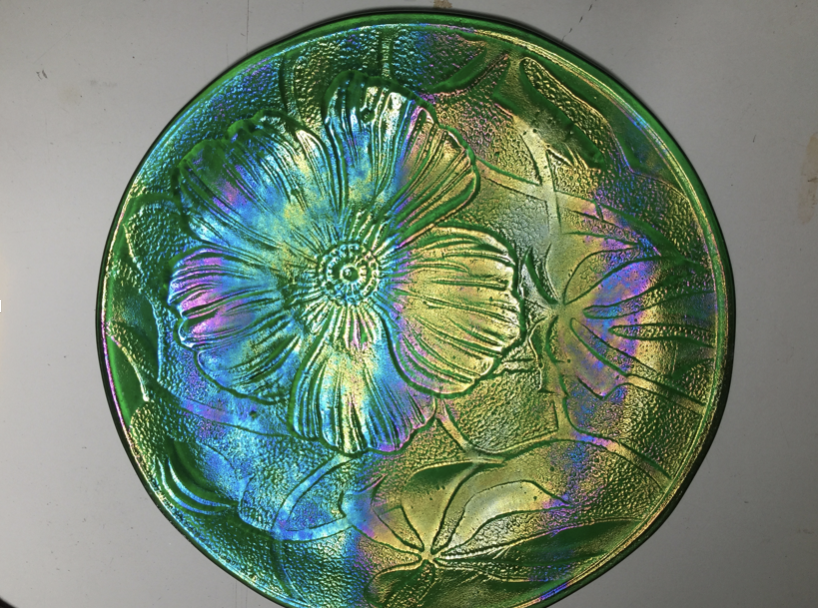

Flower Power Texture Mold - 11” $42

2 layers no prefire (use clear powder between layers)

250/1100/20

50/1225/20

450/1420/5

9999/950/90

100/700 off

Glass 2 layers Prefired

250/1420/5

9999/950/90

100/700 off

Tulip Wreath Texture Mold - 8 1/2” $38

2 layers no prefire (use clear powder between the 2 layers)

250/1100/20

50/1225/20

450/1420/5

9999/950/90

100/700 off

Glass 2 layers Prefired (I have not been prefiring mine)

350/1420/5

9999/950/90

100/700 off

350 at the beginning works for these as they are small but can also be slowed down to 250 when fired with others that are larger.

I am cutting the glass 8 1/2” on these. It is close enough to the edge of the design to get the irregular shape which I like.

Star Round Texture Mold - 9 1/2” - $38

On this mold for some reason I get a few bubbles around the star if I just fire the 2 layers of glass on the mold……try it both ways…..

Glass 2 layers no prefire (use clear powder between the 2 layers)

250/1100/20

50/1225/20

450/1420/5

9999/950/90

100/700 off

Glass 2 layers after Prefiring

350/1420/5

9999/950/90

100/700 off